Batch mix plants designed for precision and flexibility on any scale.

ALmix Batch Mix Asphalt Plants | Overview

ALmix ALB-1500 Batch Plant Tower with Built-in storage silos

ALmix supplies the industry with a complete range of batch mix asphalt plants and auxiliary equipment allowing for a level of customization ideal to fit any individual contractor’s needs. The ALB series and Travel Pack Batch plants are newly engineered to meet the need for high-consistency mix quality of the most demanding producer. The plants can be relocatable, completely portable or containerized. They may be fully enclosed to meet stringent urban environmental standards. Both the ALB and Travel Pack Series offer the latest batch mix plant features, they are well built, highly dependable and are offered in production ranges from 50 to 600 TPH.

Why Choose a Batch Mix Plant?

Precision control of aggregates

Precision control of dust, liquid AC and additives

Dramatically less waste

Ability to change mix design per batch with zero material waste

Option to do away with high-wear drag conveyors

Tower enclosure to reduce emissions and noise

Smaller overall plant footprint

Wide range of equipment adaptability for high flexibility in asphalt production

High flexibility to choose a wide range of material gradations with matching vibrating screen meshes

Easy to incorporate recycled asphalt materials with precise weighing of RAP

Twin shaft pugmill for compulsory mixing to produce high-quality homogenous asphalt mix

Option to incorporate multiple hot mix silos under the pugmill on the same plant footprint

ALmix Batch Mix Asphalt Plants | Configurations

ALmix ALB-7000 Batch Plant

Batch Mix Asphalt Plants

ALMIX ALB + ALH SERIES

ALmix stationary asphalt plants have gained wide recognition for achieving high production rates while maintaining the strictest standards of mix quality. High production plants combined with bulk storage facilities in a fixed location empowers the contractor to provide different types of asphalt mixes to store in multiple silos.

Batch mix asphalt plants are well engineered to meet customer needs for high consistency mix quality and long term production requirements. They are readily containerized and easily transportable. Our ALB Series offers the very latest batch mix plant features including advanced features exclusively offered for high-volume producers.

ALMIX tp-2500 Mobile Batch plant

Portable Batch Mix Asphalt Plants

A WIDE RANGE TO MEET EVERY CUSTOMER’S NEEDS

The ALmix Travel Pack asphalt plants are our fastest selling mobile plants on the market. They have become the first choice among contractors who are looking for a high performance plant with the ability to move and be set up fast for many years of operation.

ALmix’s Travel Pack range of fully mobile asphalt mixing plants feature a production capcity ranging from 50 - 250 TPH. It is ideal for job sites requiring 2,000 - 200,000 tons of hot mix asphalt. The Travel Pack comprises of essential equipment that may be configured into Mobile Batch Mix Plants or Mobile Continuous Mix Plants as per the individual contractor’s requirements.

HIGH MOBILITY + FAST SETUP

The Travel Pack can be towed in and set up within a few days, providing flexibility to move between sites. All of the units have been made “container-friendly” to reduce shipping cost. Assuming adequate grade conditions prevail, no concrete foundation is required to set up the plant. The Travel Pack uses the “Plug + Play” concept for each module to facilitate quick and easy setup anywhere and anytime it is needed.

ALmix Batch Mix Asphalt Plants | Features

ALmix Batch Plant Cold Feed Bins

COLD FEED SYSTEM: Built to withstand the constant abrasion of aggregates and occasional front-end loder contact. Each compartment includes at quick release gate and “no-flow” switches to warn the operator. All belt feeders are powered by direct coupled gear motors driven by flux vector drives (VFDs) to provide 100% torque at all speeds.

AGGREGATE PROCESSING: ALmix designs and manufactures a flexible line of aggregate screening conveyors and systems that allow producers to meet the highest mix specification requirements. These solutions include a variety of conveyor solutions that incorporate single deck or double-deck vibrating screens and weigh conveyors that allow operators to ensure proper aggregate sizing and weight virgin material is conveyed into the batch plant’s drying system.

For more information on ALmix’s Cold Feed Systems visit our Virgin Material Handling page.

ALmix batch mix drying system

DRYING SYSTEM: The ALmix batch mix drying system consists of a counter-flow dryer powered by four-wheel friction drives. The drying drum features two one-piece forged steel tires that rotate ton case-hardened trunnions. On the drying drum’s interior, Herringbone veiling flights facilitate an efficient drying process. The ALmix fully modulated burner with compressed air atomization provides complete and efficient combustion with excellent fuel economy and a high turn down ratio of 1:10.

Vibrating Screen on ALB-7000 Batch Tower

SCREEN WEIGHING SYSTEM: The ALmix screen weighing system consists of an effective set of inclined vibrating screens for the highest aggregate grading accuracy. Adjustable vibrators, which ensure steady movement of the aggregate through the screen system, are mounted outside the hot and dusty enclosure for long life and easy maintenance. ALmix’s digital weighing system with high-response and high-resolution provides fast and accurate weighing of asphalt, aggregates and filler from the control house.

ALmix ALB-7000 Pugmill

HIGH SPEED MIXING SYSTEM: The pugmill is the heart of the ALmix batch mix plant. The ALmix mixing system features synchronizing gearboxes that are designed to eliminate the wear and tear of conventional timing gears, coupled with reversible paddle tips designed to increase the life of the paddles. With our mixing system’s 50% live zone rating, producers achieves homogenous mix in shorter mixing cycle time. Reversible paddle tips increase the life of wear parts.

Synchronized Gearbox on Pugmill

ALmix Baghouse at Batch Mix Plant

DUST COLLECTION SYSTEM: The ALmix batch plant dust collection system uses bag filters with a built-in, inertia-style pre-seperator and reverse air rotary cleaning mechanism. The result is a longer filter bag life while meeting the most stringent air pollution control requirements.

ALmix Pollution Control Systems:

Can be designed to meet any emission standards

Allow the collection and transfer of dust, which can be customized to your operation’s specific needs

Have the option of a VFD-driven exhaust fan for automatic control

Include a high temperature safety cut-off system as well as negative pressure indication

For more information on ALmix’s Baghouses and air pollution control, visit our Emissions Control page by clicking or tapping the button below.

ALmix ALB-2500 Batch Mix Plant with three built-in hot mix silos

BUILT-IN HOT MIX SILOS: One of the key advantages that ALmix Batch Mix Plants offer to producers is the ability to incorporate multiple hot mix silos underneath the plant’s pugmill unit. The incorporation of built-in silos does away with the need for high-wear drag conveyors and the maintenance that comes along with them. Additionally, the incorporation of this style of silo has no increase on the plant’s footprint as they are constructed directly under the plant’s pugmill.

RAP System on ALB-1500 Batch Plant

RECYCLED ASPHALT PAVEMENT (RAP) USAGE SYSTEM: ALmix produces a series of mobile and stationary equipment that allows producers to incorporate RAP into their mixes. RAP bin units are available with 1 to 3 RAP bins, with the option of 20 or 30 ton bin capacity. Like our Cold Feed Systems, each bin feeder is driven by a VFD drive. which allows for automatic feeder control during production. Our RAP systems include no-flow switches, bin vibrators and air cannons to ensure the flow of material. Additional RAP processing units that include screens, breakers and weigh scales are available and customizable to your specific needs.

For more information on ALmix’s RAP systems, visit our Recycled Material Handling page by clicking or tapping the button below.

ALmix Batch Mix Asphalt Plants | Control System

The ALmix Batch Control is gold standard in accuracy. Each aggregate ingredient is initially proportioned according to the mix design by the belt feeders. After the drying process, the aggregates are individually screened and stored in the hot bins. They are then individually drawn and weighed by NTEP-approved weighing devices accurate to the nearest pound. RAP is similarly weighed and added. Finally, any fillers and additives are weighed and liquid asphalt is weighed and added to the accumulated weight of all the other ingredients. No varying process rates or time delayed injections are relied upon, so there is no need to cross your fingers waiting to see what your final AC content is. Batch ingredient weights are recorded.

ALmix Batch Plant Controls

BATCHING & BLENDING CONTROLS

Blend aggregates, liquid asphalt, RAP, mineral fillers and additives

Store unlimited number of mix designs

Computerized cold feed blending controls

Graphical user interface provides intuitive plant control

Printing facility for daily reports and tickets

Remote support via internet connection

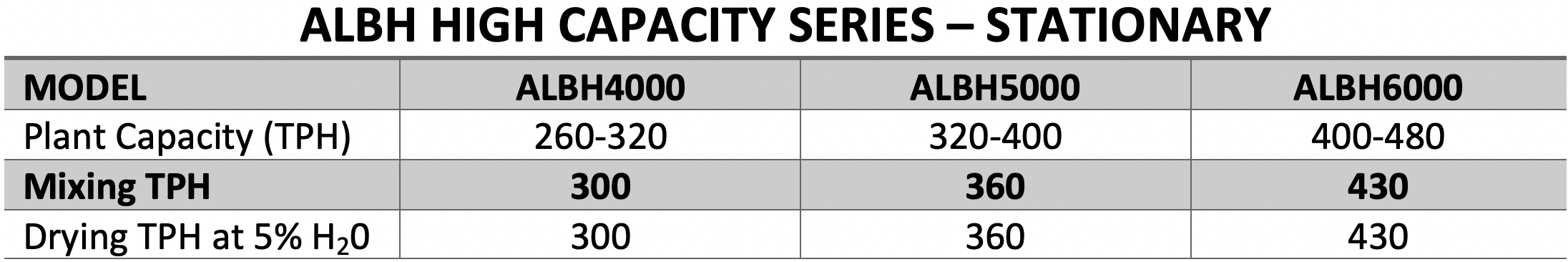

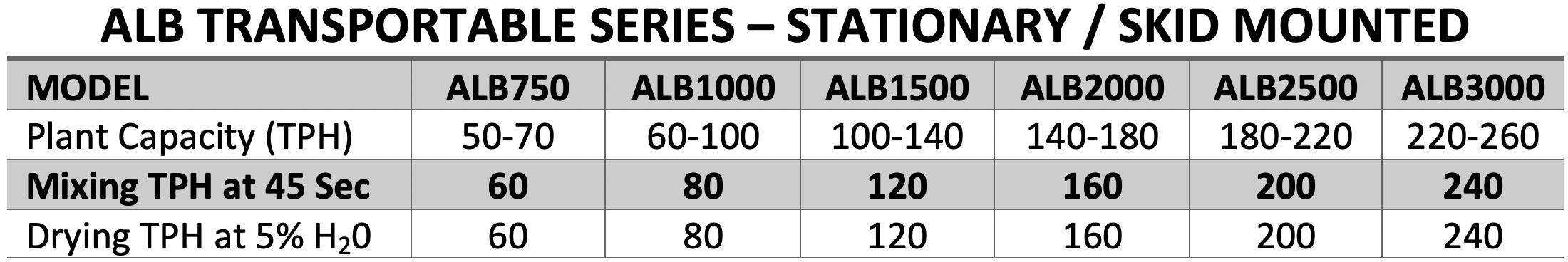

ALmix Batch Mix Plants | Capacity Ratings

ALmix Batch Mix Plants | Installation

You can rely on the experienced team at ALmix to help with the complete, turn-key installation of your ALmix Batch Mix Plant. No matter if you’re around the corner or around the globe, our crew can erect a batch plant anywhere.