Baghouses are key to your plant’s production and airflow.

ALmix Reverse Air Rotary Baghouse | Overview

ALmix Portable Baghouse

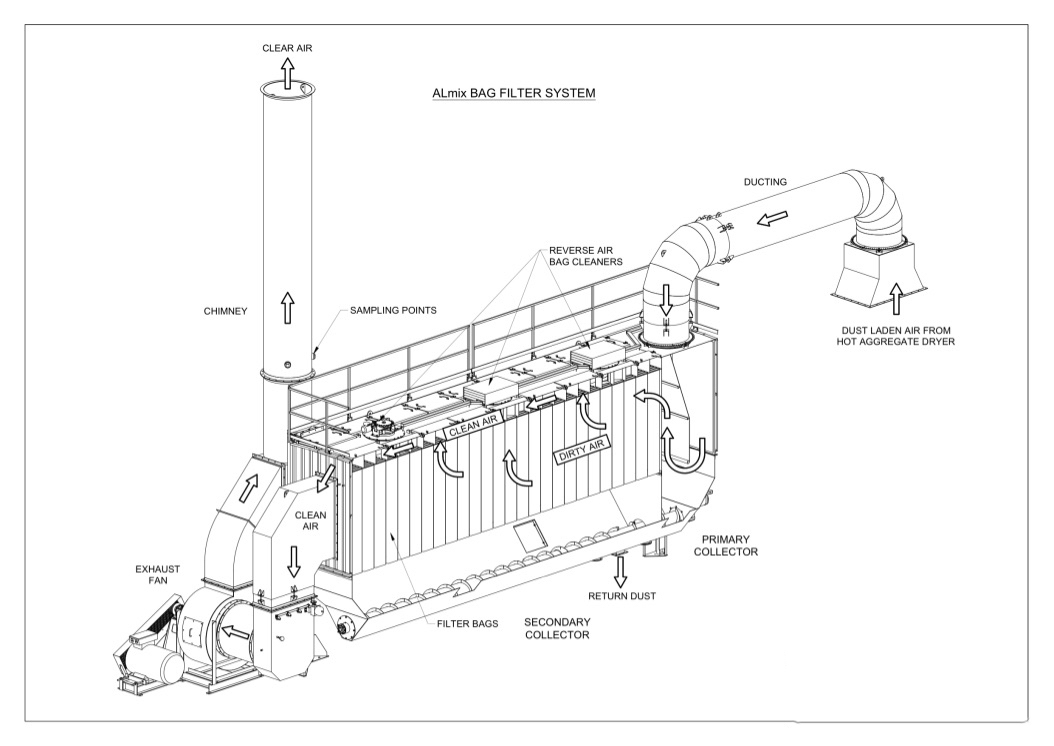

The ALmix Reverse Air Rotary Baghouse is a continuous-duty, modular collector with bag-style filters. The baghouse is used to collect airborne dust and particulate in the asphalt plant’s exhaust gasses. The simple, reliable design efficiently handles both low and high volumes of dust and provides plant operators with value through the ability to return dust and fines to the mix. Continuous duty means that the baghouse filter bags are cleaned in sequence, one set at a time without turning the unit off. The filter bags encompass a large filter area in a small compact housing thus keeping the air velocity through the bag to a very low level when compared to traditional pulse jet baghouses.

A low dryer velocity coupled with a low air-to-cloth ratio results in high performance. These principles are stictly adhered to at ALmix. Dryer velocities are held below 1,000 FPM and air-to-cloth ratios are held below 5-1. Primary collectors are not required. ALmix baghouses can be customized to fit your plant’s exact requirements and have the option to feature a return dust system that includes a variable speed waste dust auger to allow adjustment of fines being returned to the mixing drum.

Take control of your emissions, leverage your dust and give your plant the airflow it needs all with one unit.

ALmix Reverse Air Rotary Baghouse | Configurations

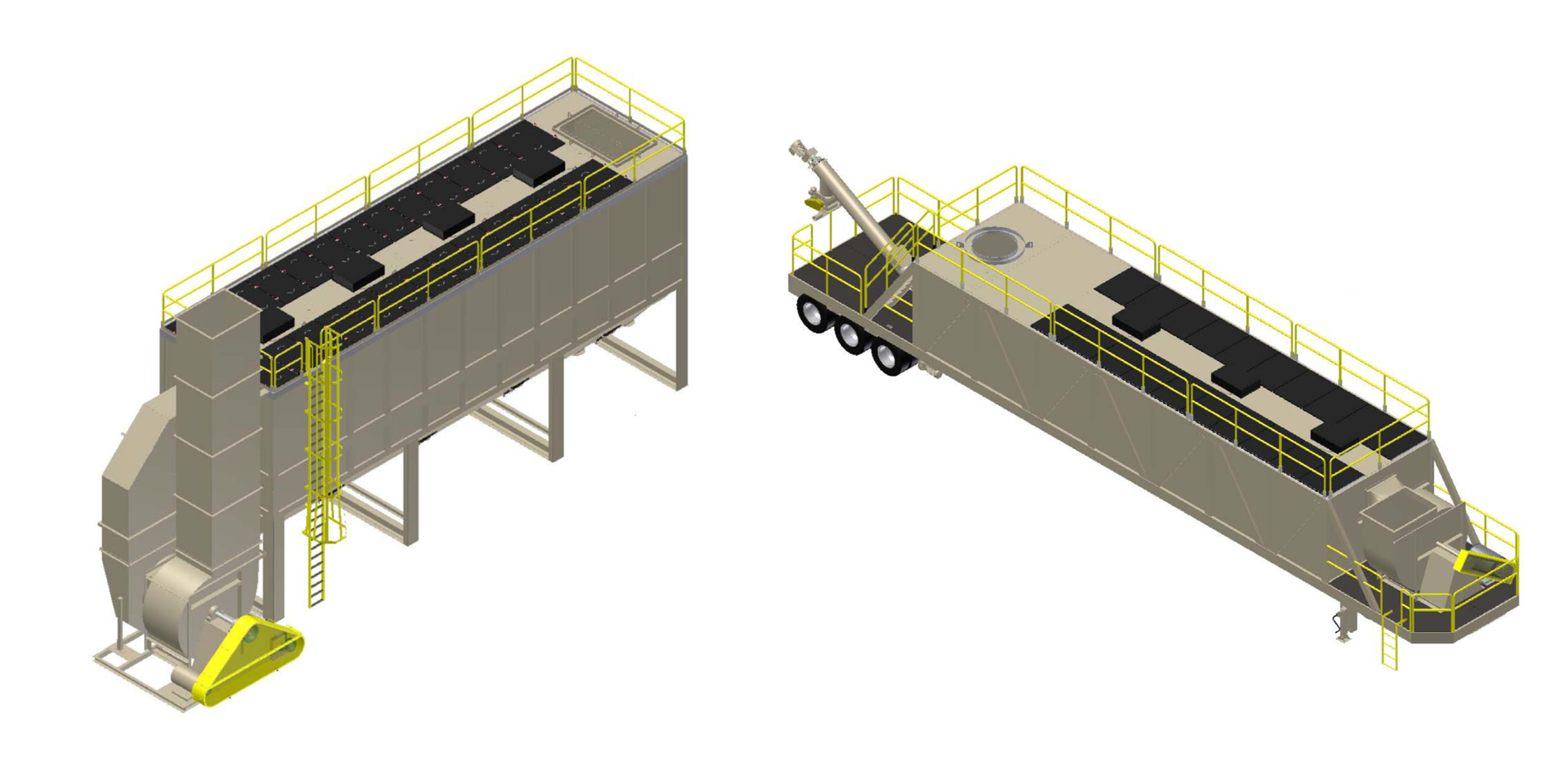

ALmix offers both portable and relocatable (skid-mounted) baghouse configurations.

ALmix relocatable (left) and portable (right) baghouses

ALmix Reverse Air Rotary Baghouse | Relocatable Configuration

Our relocatable baghouse features steel legs to grade and steel plate foundations to allow mounting the baghouse on a concrete slab rather than through the use of concrete piers. Baghouses can be constructed with optional extended legs to allow for a desired clearance height under the baghouse unit.

The baghouse hopper section contains a 16” diameter screw conveyor that runs the full length of the baghouse to bring captured dust to the return dust system.

The dust auger includes a magnet-mounted zero speeed sensor to signal the total control of motion. All auger motors are equipped with VFDs to regulate speed.

ALmix Reverse Air Rotary Baghouse | Portable Configuration

Our portable baghouse unit comes fully portable on a trtiple spring mounted, 5” diameter axle assembly with dual tires and wheels, turn and stop lights, fifth wheel pin, air brakes and mud flaps. Adjustable jack legs with steel foundation plates are provided.

The portable baghouse design features two 12” hopper augers, a 12” cross auger and a 12” inclined auger that work together to convey captured dust to the return dust system. The baghouse hopper includes cleanout plugs located the full length of each screw trough. Each dust auger includes a magnet-mounted zero speeed sensor to signal the total control of motion. All auger motors are equipped with VFDs to regulate speed.

ALmix Reverse Air Rotary Baghouse | Cleaning Process

ALmix reverse-air baghouses are compartmentalized to allow for continuous operation. Before a cleaning cycle begins, filtration is stopped in only the compartment to be cleaned, which occurs by injecting clean air into the dust collector in a reverse direction, which in turn pressurizes the compartment. The pressure makes the bags collapse partially, causing the caked on dust to crack from the filter bags and fall into the hopper below. At the end of the cleaning cycle, reverse airflow is discontinued, and the compartment is returned to the main stream.

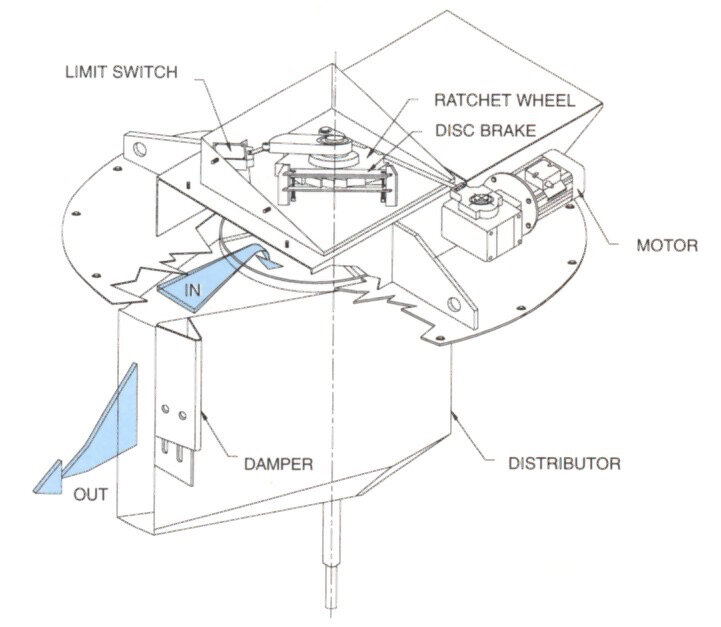

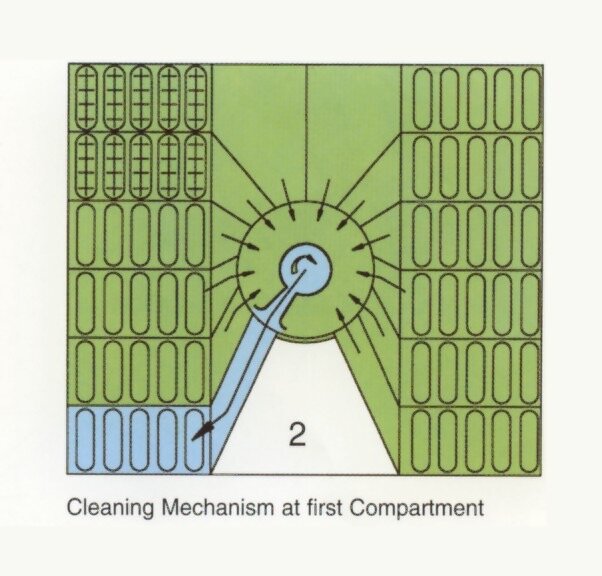

Cleaning nozzle drive sequence

The cleaning nozzle drive and sequence mechanism, (pictured above) consists of a right angle gear motor with rotating eccentric drive shaft that engages a central sprocket. The mechanism moves the cleaning nozzle from row to row quickly but allows the nozzle to pause momentarily at each row. The cleaning mechanism automatically starts cleaning according to a preset time which is adjustable by the plant operator. After the nozzle completes a full cycle and returns to its parked position, a sensor cuts off power to the cleaning mechanism gear motor. The baghouse requires no compressed air for cleaning.

ALmix Reverse Air Rotary Baghouse | Features

BAGS: Bag design is of the single wall type, elliptical design. The surface of the bag is singed prior to manufacture to insure better cake release during the cleaning operation. The bag opening is provided with a flexible spring collar, which assures easy installation and replacement. This flexible collar locates, locks and seals the bag in position. The bags are arranged in sections including removable covers for inspection and replacement.

Elliptical bags hanging over baghouse hopper auger

ALmix baghouse exhauster and motor

BAGHOUSE EXAUSTER: The baghouse exhauster plays a crucial role in your plant’s production. The airflow and pressure drop in your plant system is derived from a high efficiency, low energy, backward inclined exhaust fan powered by a fully digital, AC flux vector drive motor. This frequency drive control eliminates the need for a soft starter and a mechanical damper while also eliminating voltage drops on fan startup. Our optional direct drive configuration eliminates the need for sheaves and multiple belts and belt guards. Test ports are installed in the stack above the exhauster for testing emissions from your plant.

DUST/FINES RETURN: The baghouse hopper sections contains screw conveyors for collecting the fine dust released from the baghouse cleaning process. The baghouse hopper auger can connect to your requested dust return setup, which conveys the collected dust to the mixing section of the drum mixer. Dust return systems can also be designed to allow for the wasting of dust if required.

Configurations for dust return systems include vane feeders, dust silos and other components for monitoring and storing collected dust and fines are available.

ALmix baghouse with dust return system and vane feeder

ALmix Reverse Air Rotary Baghouse | Primary Collectors

PYRAMID-STYLE PRIMARY COLLECTOR: If desired, a pyramid-style primary knockout box collector can be mounted over the drum frame to collect heavy fines in the exhaust gas stream before they enter the baghouse. Once collected, the fines are dropped into a sloped hopper and trickle valve. These fines can then be discharged into the drum’s RAP collar. Capturing these larger particles lessens the wear on the bags and increases bag efficiency while simultaneously lubricating the Rap Collar.

BAGHOUSE-MOUNTED INERTIAL COLLECTOR: An optional intertial primary collector can be mounted at the inlet side of the baghouse, following the ductwork connecting the drum to the baghouse. This integral inertial expansion area is designed to capture the larger particles of dust. This is accomplished by a dramatic change in air flow velocity and direction. As dust-laden air enters the baghouse and is guided through the intertial collector, heavy dust particles collide with the bars on the collector and drop to the hopper below, knocking out heavy fines before they enter the baghouse bags. Material collected by the inertial collector is gravity-fed directly to the return dust screw, circumventing the baghouse hopper auger.