Our RAP systems provide sustainability on any scale.

ALmix Recycled Material Processing | Overview

Recycled Asphalt Pavement or RAP continues to be a driving component of today’s asphalt mix designs. Incorporating an ALmix RAP System at your plant is the solution for asphalt producers looking to utilize and process RAP for their mixes, with customizable options that help any producer meet a wide range of mix recycling goals. Like all ALmix products, our line of RAP Systems is built heavy and is engineered to take the daily abuse associated with high-volume plant production. All while incorporating the features and details that allow for the precise RAP feeding required with today’s high-spec mixes.

ALmix RAP Feed Bins | Overview

ALmix offers both fully portable and skid-mounted (relocatable) RAP feeder bin designs in multiple bin sizes to meet the meeds of a wide variety of contractors.

Skid-Mounted RAP Bin Unit

Portable RAP Bin Unit

ALmix RAP Feed Bins | Features

ALmix RAP bins feature many of the same rugged features seen in our Cold Feed Bins, however, our RAP bins are specially designed to aid in the flowability of sticky RAP materials while providing the extreme accuracy and precision required for dosing RAP.

ALmix RAP FEEb BIN

DURABLE BINS

All of our bins are constructed from 1/4” steel plate and top lip and mid-bin sections are reinforced with 3/8” bent steel plate for added strength and durability. Each bin gate is outfitted with a heavy duty screw jack for adjusting the gate opening as well as lockable gate positions with index. Bin bottoms are designed with self-relieving throats aid in material flowability and reduce drag on the feeder sides. Rotary electric vibrators to prevent material bridging come standard, and each recycle bin is fitted with a grizzly constructed from 1/2-in. x 6-in. flat bar to reject oversized materials and to provide a smooth surface for the loader bucket.

BIG TIME GEARBOXES

Each RAP bin feeder incorporates a direct-connected helical gearbox and fully-digital flux vector technology allowing the flux vector drive to produce 100% torque at zero speed without overheating. This means that even at low feed rates with the stickiest materials, your ALmix RAP bins feeders are designed to keep rolling material out without overheating.

DETAILED RAP BIN FEEDERS

To start, our RAP bin feeders use troughing idlers to prevent material spillage without the need for additional rubber flashing. To alert the plant operator if material ceases to flow from any RAP bin, each RAP bin feeder is equipped with a material flow detector and the RAP bin feeder tail shaft is equipped with an optical encoder which allows automatic feeder control through the ALmix Insignia Control System. The RAP bin feeder idlers and tail pulleys are guarded with perimeter-reinforced wire mesh guarding. All grease zerks are extended beyond the guarding for easy access.

Additional RAP Bin Features

Our RAP bins are fully customizable with the latest optional features.

Bin Extensions

Bin Dividers

Cable Trays

Built-in Retaining Walls & Bulkheads

Emergency Pull Cords

Walkways

Built-in Scalping Screens

Weigh Feeders

Moisture Probes

Bin Level Indicators

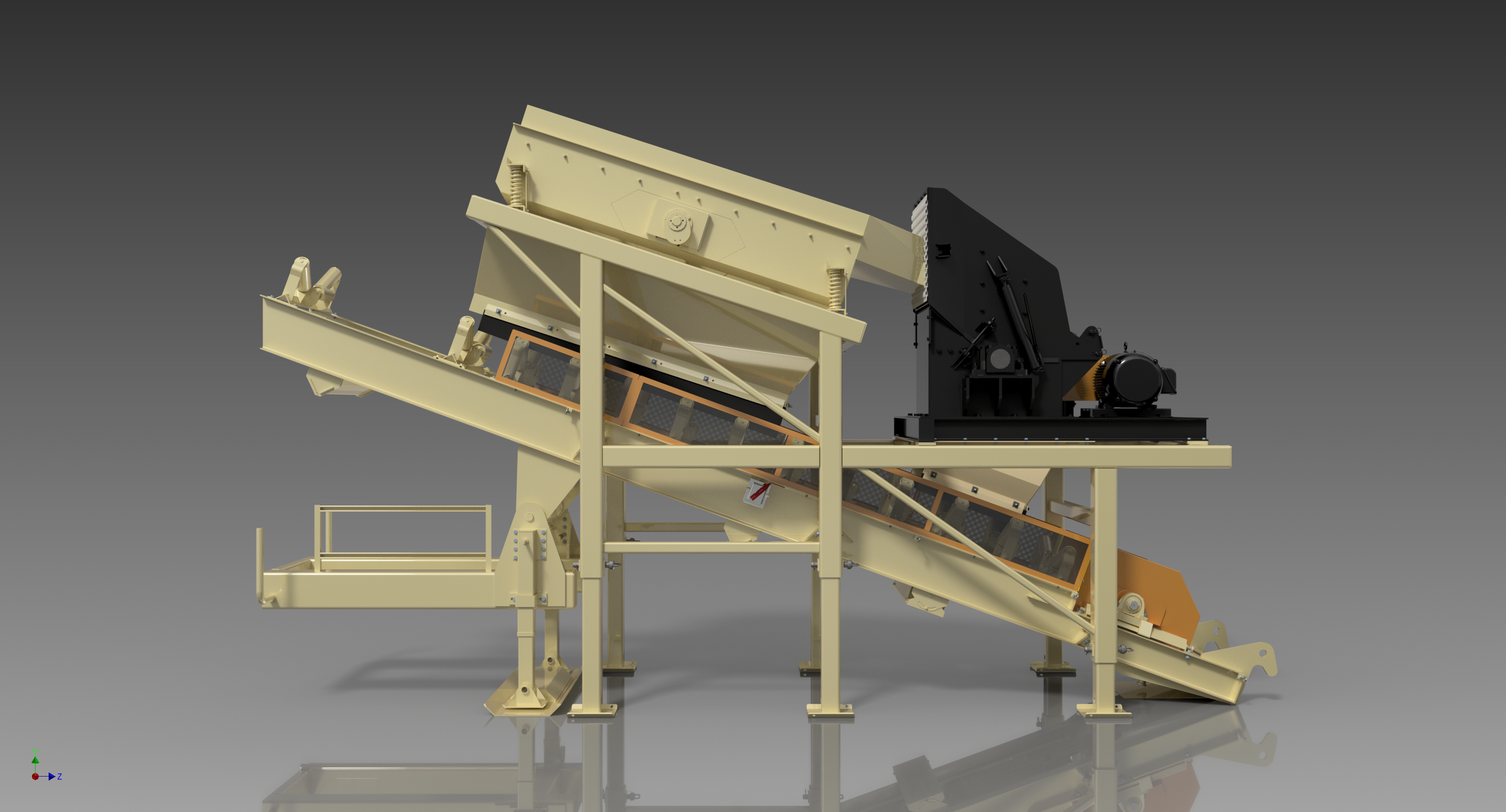

ALmix Rap processing System with vibrating screen and RAP Crusher

ALmix Recycled Material Processing | Overview

ALmix RAP capabilities at the asphalt plant go far beyond just RAP bins. Like our Cold Feed Systems, ALmix provides a full line of customizable RAP proceessing systems in order to allow your operation to process even the most difficult RAP pile. These systems are available in both skid-mounted (relocatable) and fully portable designs.

RAP SCREENING

RAP screening is a crucial step at the asphalt plant to ensure any oversized materials or foreign debris are screened out of the process. This is typically accomplished through the use of a vibrating screen deck incorporated into the RAP system. A single or double-deck deck scalping screen can be provided as a modular unit mounted over the RAP weigh conveyor on a heavy H-beam frame that includes base plates and side support steel. The scalping screen’s vibrating motion is driven by a motor mounted on a heavy duty pivoted motor base. ALmix RAP bins can also be designed to incorporate a single-deck RAP screen above the collecting conveyor without the need for a separate screening conveyor.

RAP CRUSHING

The ALmix line of RAP crushers are designed to crush oversized RAP pieces that enter your plant’s RAP processing process. RAP crushers can be mounted to the discharge chute of your RAP scalping screen where the crusher unit will process any rejected material from the screen and return it to the process by dropping the crushed RAP on the conveyor belt below. RAP crusher systems include a cross-belt magnet ahead of the crusher, designed to remove any metallic debris. Additionally, RAP crushers can be incorporated as part of a closed-loop, run-around system in which material discharged from the RAP crusher is re-screened by the RAP scalping screen.

RAP WEIGH CONVEYORS

The final phase in the process of including RAP at the plant is weighing the screened and processed RAP material before it heads to the drum mixer. The ALmix RAP weigh conveyor contains the recycle weighbridge with speed sensor and test weight. This weigh bridge sends a continuous rate back to the control system for the blending process. Wind guards are provided to insure accurate weighing. The load cell is insulated top and bottom with ceramic isolators and includes a heavy ground strap around the load cell for lightening protection. An air operated by-pass chute is provided on RAP weigh conveyors to allow belt scale calibration and feeder bin clean-out.